Enabling Programs

Critical to the development of these products are Ionic’s enabling technology programs:

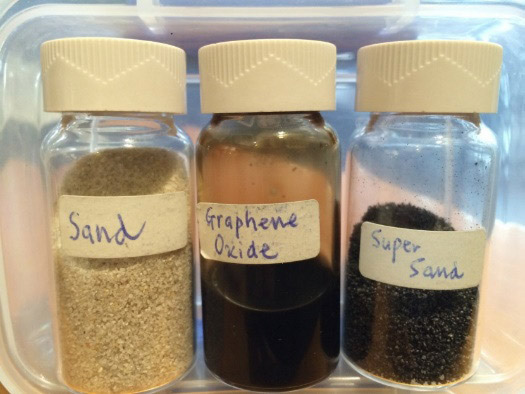

- Our bench-scale graphene oxide facility enables the specialised tailoring of graphene materials for use in a range of applications

- Our pilot plant project is the first stage in upscaling our production of graphene oxide, which is the primary material that all of our technologies are based on

- Our graphene printing facility produces graphene membranes which are the primary component in our nano-filtration products.

Bench-Scale Facility

Ionic has recently commissioned a bench-scale facility for the production of graphene oxide in collaboration with Monash. The facility, under the supervision of Associate Professor Majumder, is assisting with the transition of graphene manufacturing expertise out of the laboratory and into commercial applications, allowing the development of expertise that is crucial to the supply of much larger quantities of tailored graphene for our specific commercial goals in SuperSand, nano-filtration membranes and super-capacitors.

With initial batches of production in the range of 1kg to 2kg per day, the bench-scale facility is a vital tool to develop manufacturing intellectual property and a key step towards the goal of commercialising our technologies and enabling the manufacture of tailored graphene products for use across all our products and applications. The ability to customise graphene oxide is important because, while graphene itself is a simple substance, the challenge of product development using graphene is developing the know-how to create novel complex structures that employ graphene’s unique properties in a tailored manner for optimised combination with other materials.

Furthermore, we are working on technologies that can be increased to multi-kilogram scales, when required, while optimising the process to make it significantly cheaper and greener. Large-scale graphene production from graphite is a significant challenge which Ionic and Monash are seeking to overcome by using robust reaction engineering approaches. The scale of the reactor at the bench-scale facility is several times what has been demonstrated by others to date and the reactor technology we are developing is highly modular which suggests it will be scaleable.

Pilot Plant

Ionic’s Pilot Plant project represents our most significant step yet toward the commercialisation of the technologies that have been developed in collaboration with Monash. To date, Ionic has commissioned and completed an engineering study, which combined with a marketing study on SuperSand, confirms the viability of the proposal. An independent engineering group was commissioned to examine the feasibility of a pilot plant to produce graphene oxide (GO) and multiple SuperSand products using Ionic’s innovative technology.

The next step is to commission construction of the plant, which will ideally be located in the Tonsley high-tech industrial park in Adelaide. With this plant, Ionic has ambitions of taking the first steps toward becoming a leading manufacturer of specialised graphene based products for major sectors of the economy. Tailored graphene oxide products may also be produced under contract in support of other technologies being developed by Ionic Industries partners or customers.

Pilot Plant Details

Our Pilot Plant will ideally be located in Adelaide’s Tonsley hightech industrial park where we expect excellent opportunities to develop collaborative relationships with industry partners, research institutions and government agencies. Being located in South Australia is not a mandatory requirement but would enable us to leverage the opportunities associated with South Australia’s leadership in manufacturing and defence sectors.

Our aim is to run the pilot plant to produce tailor made products for specific customer needs, including our own SuperSand production, with a view to eventually upscaling the plant to target higher production volumes and broader market opportunities both in Australia and overseas.

The majority of the pilot plant facility is housed in a modified container. Services and SuperSand mixing/drying is housed on separate skids, allowing for flexibility in the location of items of plant.

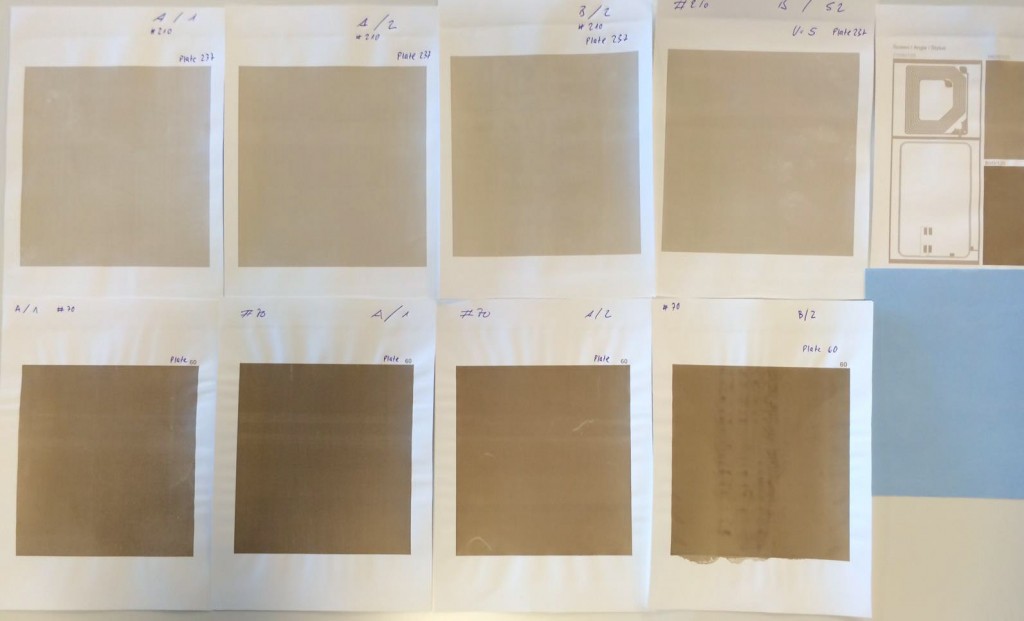

Laboratory product

Graphene Membrane Casting Facility

Samples of our graphene thin film membranes – darker shades indicate greater number of layers of graphene

In early 2015, Ionic Industries acquired a membrane casting facility for our graphene membrane technology. This membrane casting facility is a very important step in our development of a scalable graphene membranes. Graphene samples produced by our proprietary method were tested with the membrane casting equipment manufacturer and we have been very pleased with the results obtained. The new acquisition enables our researchers to tailor the number of sheets of graphene that can applied to the membrane substrate for specific purposes. The chemistry of the graphene oxide can also be altered to target whatever impurities or precious metals we seek to filter. Another key benefit is being able to maintain consistency between the batches of membranes produced. This will facilitate us in more effectively substantiating our results during testing phases.