SuperSand

Ionic is collaborating with Monash with respect to the intellectual property that underpins the SuperSand product as a Project under the Collaboration Agreement. Ionic accordingly holds the exclusive option to licence the intellectual property generated by Monash and that relates to SuperSand.

Ionic Industries plans to realise initial revenue streams from the sale of SuperSand in 2016 or early 2017 following completion of our Pilot Facility.

Technology

SuperSand involves the application of a graphene coating to sand particles for use in water treatment and chemical separation technologies.

SuperSand involves the application of a graphene coating to sand particles for use in water treatment and chemical separation technologies.

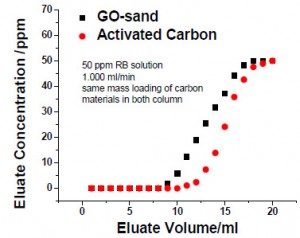

SuperSand represents a substitute or replacement for activated carbon, with the advantages of a larger surface-to-volume ratio, customization to capture different pollutants, customization of particle/pore sizes and an unlimited range of product streams derived from the same parent process. As such, Ionic plans to target the global activated carbon market and position SuperSand as a potential disruptor of that existing market.

The research team is currently undertaking a detailed mechanistic study. This technology is at a Technology Readiness Level (TRL) of 5 and we are aiming for a TRL of 9 by 2016, with production in commercial quantities at our planned pilot plant. The Pilot Plant will serve as a critical step in our upscaling to greater levels of commercial production.

Markets

Ionic commissioned and completed an independent marketing report on SuperSand as a potential participant in the global Activated Carbon (AC) market. The review was completed by The Freedonia Group, Inc, which has its main headquarters in Cleveland, Ohio, USA and a satellite office in Beijing, China. The Freedonia Group is a leading international business research company that provides critical market research through the publication of more than 400 research studies annually and customized research engagements for clients.

Global activated carbon (AC) demand was 1,550,000 metric tons ($4.8 billion AUD) in 2014, with overall annual growth projected to exceed 7% through 2019 and 6% thereafter through to 2024.

Powdered Activated Carbon (PAC) is the primary product of choice, with 2014 demand of 785,000 metric tons ($2.4 billion AUD). Demand for PAC is projected to grow at a faster rate than overall activated carbon from 2014 to 2019 at 9.4% per year, driven by growth in mercury removal applications in air purification.

Granulated Activated Carbon (GAC) demand was 725,000 metric tons ($2.2 billion AUD) in 2014, and is expected to grow at 4.8% per annum.

Other forms of activated carbon that are used in specialty applications, including chemically impregnated carbons and activated carbon cloth. Demand for these products is predicted to increase at a moderate rate of 2.3% per year from 2014 to 2019, due to the high prices of most of these product types.

The focus of Ionic’s SuperSand marketing efforts will be industrial air purification, drinking water treatment and food and beverage processing.

Industrial air purification

Industrial air purification is expected to overtake water treatment as the largest AC market segment by 2019. Increasing restrictions on mercury emissions from industrial processes will drive this trend, which will be increasingly beneficial to demand for PAC.

- The market for mercury removal, flue gas treatment and other gas phase applications – particularly solvent recovery in coatings, adhesives and printing inks– appears viable for SuperSand as a replacement to AC. Our ability to produce different sizes and performance factors for SuperSand means we may be able to optimize it for each of these applications. SuperSand properties suggest it would be applicable in the mercury removal and solvent recovery markets.

- Flue gas treatment and mercury removal generally require adsorbents that are effective within the few seconds that it takes the gas to transit through the process. SuperSand is suited to this application because of its surface structure.

- Solvent recovery requires the ability to differentially absorb molecules of different sizes, and the tailor-ability of the pore sizes in SuperSand would make it suitable for such applications.

Drinking water

Population growth is increasing the need for improved drinking water in developing nations, as well as increased water-purity regulations in developed areas. This trend will have a positive impact on the overall AC market for water treatment. Municipal water treatment is by far the biggest contributor to demand, while residential uses make up a smaller portion. SuperSand fits within GAC water treatment applications due to the large pollutant particle sizes that need to be removed. SuperSand usage will also benefit applications with a higher loading rate of water such as large water treatment systems designed to remove synthetic organic compounds.

Food and beverage

Within the food and beverage segment, AC is used in applications such as cane sugar refining, liquid sugar purification, alcoholic beverage purification, fruit juices (to remove colorant), biochemical food products (to absorb molasses colorants as well as acids), lactose purification, flavouring decolourisation, oils, natural glycerin and decaffeination of coffee or tea.

Ionic Industries will pay particular attention to applications of SuperSand in the wine and dairy industries. We believe SuperSand will be especially effective in dairy and wine processing including lactose removal, tartrate stabilisation and smoke taint removal. In the longer term, we aim to target niche markets such as lactoferrin production in the dairy industry.

Next steps / potential customers

As the most developed technology and the most likely to generate return on investment in the near term, this research stream will be prioritised in terms of allocation of capital.

The SuperSand project will progress through a series of four testing phases (prior to Ionic’s goal of production commencing in 2016) that include: comparison testing, scale testing, treated water testing; and production from pilot plant.

Ionic Industries will be working with SA Water to develop tailored SuperSand products for the removal of various contaminants in drinking water, ranging from natural organic matter to taste and odour compounds. The initial laboratory tests will use samples of the water to be treated and, building on those initial test results, tailored SuperSand products will be manufactured to target specific contaminants. Once the research team has confirmed the performance of the specialised product then the next step will be to trial it in one of the many SA Water test facilities.